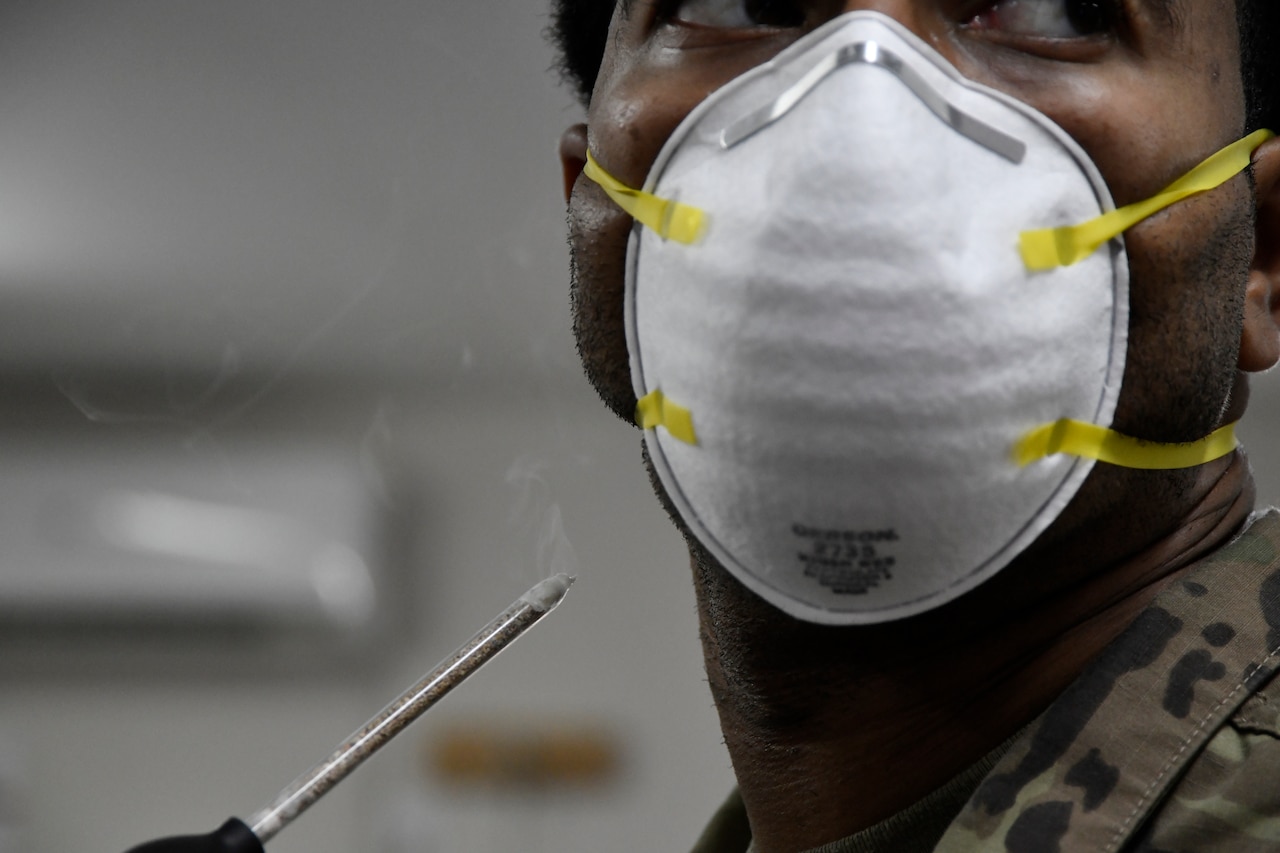

A Defense Logistics Agency laboratory known for burning boots, crushing helmets and ripping combat uniforms is also putting COVID-19 personal protective equipment through the same grueling tests — all in the name of safety and product conformance.

Co-located with DLA Troop Support in Philadelphia, where it tests items primarily in the clothing and textiles and construction and equipment supply chains, the Product Test Center — Analytical is staffed with 27 employees including scientists, engineers and textile technologists.

“Think of us as the Consumer Reports for DLA. We don’t just test when there’s a problem; we test to make sure vendors meet contract requirements and warfighters have functional items that work as they’re intended to in the field,” said Jamie Hieber, the Product Test Center — Analytical manager.

The group performed more testing in 2020 than ever despite the limited number of people who could work in the lab simultaneously under pandemic restrictions. And adding time-consuming analysis of items like masks and gowns to the routine hasn’t caused them to miss a single deadline, Hieber added.

When the military services began purchasing fabric face masks for troops in the spring, Jessica Raushel’s analytical team was asked to evaluate a fabric one vendor claimed had the ability to bind to chlorine.

“If you washed the fabric, it was said to hold on to the chlorine, which would then be released during use of the fabric and potentially give it anti-microbial properties. We were asked to verify that the fabric was indeed treated with this extra finish,” she said.

The team wasn’t asked to test the fabric’s protective properties but did provide contracting officers information they needed to make decisions on whether the chlorine-treated fabric posed potential health risks. Hieber said the group takes pride in sharing science-based data even though they don’t always know whether the products tested are later purchased.

Other mask tests included a durability analysis of the head harnesses for KN95s, a mask that’s more easily available in the U.S. than N95s although it offers less protection.

Uraina Gray-Scully’s shade and textiles’ team also tests the durability of surgical gowns from numerous vendors. The gowns are put through 25 wash cycles using parameters such as water and heat temperatures set by manufacturers. Testing can be rigorous and involves commercial or front-loading washers as well as basic home washers.

“The things we look for range from whether the care label is legible after 25 cycles to the side and neck ties holding up without unraveling, and if there are any holes, rips or tears in the body of the gown,” Gray-Scully said.

Gown testing takes over a week with five cycles per day for five to six days plus an additional day for staff to write the report.

In non-COVID-19 work, much of the lab’s labor revolves around routine checks of performance characteristics for items like combat boots. The tests include an analysis of bond strength between different layers of the sole to ensure it stays together and evaluation of the moisture vapor transmission rate to measure how quickly the boots dry out.

“For flame-resistant combat boots, we’ll also test a variety of heat and flame-resistant characteristics like sole heat resistance, which measures the ability to insulate the foot from damage when walking on a hot surface and also upper heat resistance, which measures the ability to protect the wearer’s ankle and lower leg from heat,” Raushel said.

Many contractors are familiar with DLA’s testing capabilities and take extra steps to ensure their products conform to contract requirements, Hieber said. Before the pandemic, contractors visited the lab as often as five times a week to observe fabric quality and color testing for uniform items. And although contractors run their own tests, DLA ensures contracting officers have unbiased results.

“I’m not saying anybody is out to defraud the government, but what if they are,” she asked. “What if we come to a situation where there’s a safety issue or the item doesn’t meet a requirement and it gets into the supply system and someone is hurt or killed because we didn’t do our due diligence?”

To adjust to the demand for testing amid pandemic conditions, the staff completed its leap into electronic record keeping and embraced the agency’s use of online collaboration tools.

“What we’ve done to support the pandemic is good news,” Hieber said. “But it’s also important to say this lab found a way to continue doing the work it’s always done in spite of all the challenges of the past year. Our customers know they can rely on us.”